Campello Restaurants Roofing | Grease Vent Risks & Safety Tips

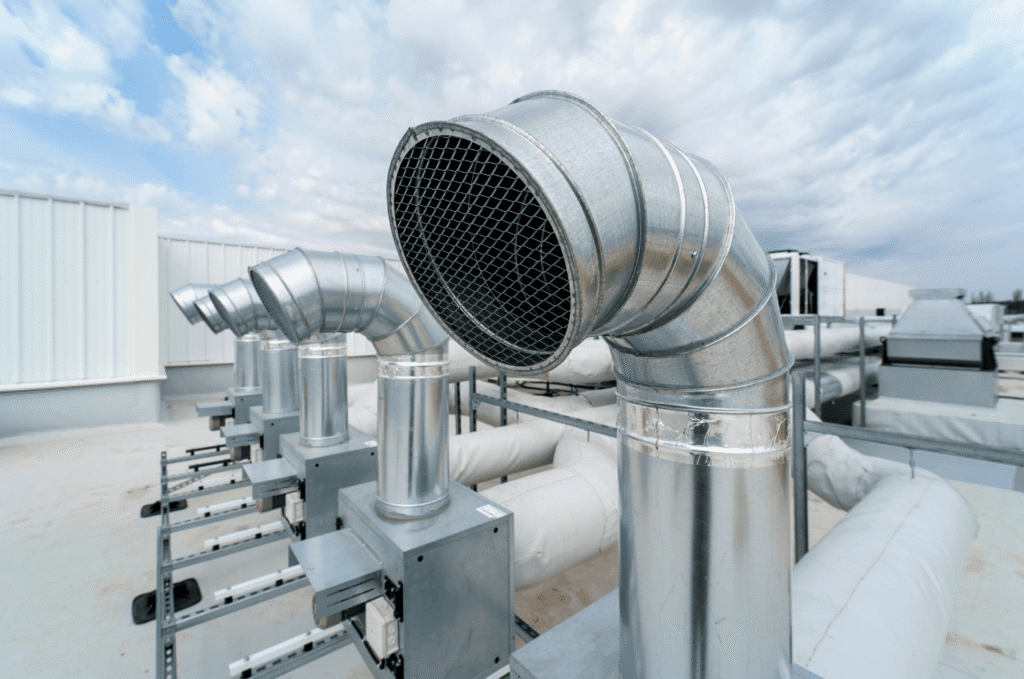

For commercial roofing projects, restaurant buildings present unique challenges that standard office or retail spaces simply don’t face. The combination of intense heat, moisture, and grease emissions from kitchen operations creates a demanding environment that requires specialized knowledge and materials.

If you’re planning a restaurant roof build or renovation, understanding how ventilation systems interact with your roofing system isn’t just important, it’s critical to the longevity of your investment.

Table of Contents

Why Restaurant Roofs Are Different

Restaurant operations in Campello generate significantly more heat and airborne contaminants than most commercial buildings. Commercial kitchens produce steam, smoke, and grease-laden vapors that must be properly vented through the roof. Unlike a typical commercial roof that mainly needs to shed water and resist UV damage, roofing for restaurants must withstand constant exposure to elevated temperatures and corrosive grease deposits.

The grease exhaust systems in commercial kitchens can reach temperatures of 500°F or higher at the vent termination point. This extreme heat, combined with grease accumulation, creates several potential failure points in your roofing system if not properly addressed during roof installation.

Grease Vent Dynamics

Commercial kitchen exhaust systems are designed to capture cooking vapors and transport them outside the building. However, the journey doesn’t end when the exhaust reaches the roof. The way these vents interact with your commercial roofing material determines whether you’ll enjoy decades of reliable performance or face premature deterioration and costly repairs.

Grease-laden vapors exit the vent stack and disperse across the roof surface. Even with proper exhaust velocity, some grease particles settle onto the roofing membrane, especially in areas immediately surrounding the vent termination. Over time, this accumulation can break down certain roofing materials, creating weak spots that are vulnerable to leaks and structural damage.

The positioning of grease vents on your restaurant roof matters tremendously. Vents placed too close to roof edges, HVAC equipment, or other penetrations can create maintenance nightmares and accelerate wear patterns. During your restaurant roof build in Franklin, careful planning of vent locations should happen before the first roofing material is installed.

Material Selection for Restaurant Roofing

Not all commercial roofing materials respond equally to the harsh conditions created by kitchen exhaust systems. When selecting materials for roofing for restaurants, grease resistance should be a primary consideration alongside traditional factors like cost, warranty, and climate suitability.

Modified bitumen roofing systems offer excellent grease resistance and have proven themselves in countless restaurant applications and flat roofing systems. The granulated surface helps resist grease penetration, while the material’s flexibility accommodates thermal expansion around hot exhaust penetrations. Many roofing contractors recommend modified bitumen specifically for restaurant projects because of its track record in grease-exposed environments.

TPO and PVC single-ply membranes are also popular choices for commercial roofing on restaurants, though they require additional protective measures around grease vents. These materials offer excellent reflectivity and energy efficiency, but the areas surrounding exhaust penetrations often need specialized grease-resistant coatings or secondary protection layers.

EPDM rubber roofing can perform well on restaurant buildings when properly detailed around ventilation equipment. However, EPDM’s susceptibility to petroleum-based contaminants means that grease accumulation areas need regular cleaning and inspection to prevent premature degradation in Kingston.

Proper Flashing and Curb Installation

The intersection between roofing ventilation equipment and the roof membrane represents one of the most critical details in any restaurant roof build. Exhaust vents must be mounted on properly constructed curbs that elevate the termination point above the roof surface and provide a watertight seal.

Curbs for grease exhaust vents should be constructed from materials that won’t deteriorate under constant heat exposure. Galvanized steel or stainless steel curbs are standard, with stainless steel being the premium choice for maximum longevity.

Flashing details around grease vents require special attention. Standard commercial roof flashing techniques need to be enhanced with additional layers of protection and heat-resistant materials. Many experienced roof repair contractors use multiple layers of base flashing overlapped with counter flashing, all sealed with high-temperature compatible sealants that won’t break down under heat exposure.

Roofing Ventilation Best Practices

Effective roofing ventilation in Milton goes beyond just the grease exhaust system. Your restaurant’s commercial roof needs balanced air movement to prevent moisture accumulation in the roof assembly and extend material life. This becomes especially important given the high moisture loads generated by kitchen operations.

Passive ventilation through ridge vents and soffit vents helps regulate temperature and moisture in the roof cavity. However, these must be positioned strategically to avoid drawing grease-laden air back toward the building or creating negative pressure zones that could affect kitchen exhaust performance.

The spacing between grease exhaust vents and fresh air intakes deserves careful consideration. You never want outdoor air intakes positioned where they might draw in grease vapors expelled from kitchen vents. This not only creates air quality issues but can also contaminate HVAC systems and indoor spaces.

Maintenance Considerations

Even the best-designed commercial roofing system for a restaurant requires regular maintenance to perform as intended. Grease accumulation around vent terminations should be cleaned quarterly at minimum, with more frequent cleaning for high-volume kitchens. This isn’t just about roof preservation, accumulated grease presents a serious fire hazard that can threaten your entire building.

Professional roof inspections should occur at least twice annually, with particular attention paid to the condition of flashing around exhaust penetrations. Small deterioration in these critical areas can quickly escalate into major leaks if not caught early. Many roofing companies offer maintenance contracts specifically designed for restaurant clients, recognizing the unique demands these buildings place on roofing systems.

The roof membrane in areas exposed to regular grease contact may need periodic recoating or patching even when the rest of the roof remains in good condition. Building these touch-ups into your maintenance budget prevents small problems from becoming large-scale roof failures.

Working with Experienced Contractors

The complexity of roofing for restaurants demands expertise beyond standard commercial roofing knowledge. When selecting a contractor for your restaurant roof build or renovation, look for demonstrated experience with food service facilities. Ask specific questions about their approach to grease vent integration, material selection for grease-exposed areas, and maintenance recommendations.

A qualified commercial roofing contractor should be willing to collaborate with your kitchen ventilation contractor to ensure proper coordination between systems. The best outcomes occur when roofing and mechanical trades work together during the design phase, not just during installation.

Long-Term Performance

Investing in proper commercial roofing designed specifically for restaurant applications pays dividends over the building’s lifetime. While the upfront cost may be higher than a standard commercial roof, the extended service life and reduced maintenance needs more than justify the investment.

A well-designed and properly maintained restaurant roof can provide 20-30 years of reliable performance, protecting your valuable kitchen equipment and preventing business interruptions from leak-related closures. Given the revenue impact of even a single day of restaurant closure, the peace of mind that comes with a robust roofing system is invaluable.

Your commercial roof is far more than just weather protection, it’s an integral component of your restaurant’s operational infrastructure.

Schedule consultation for your new commercial project today.